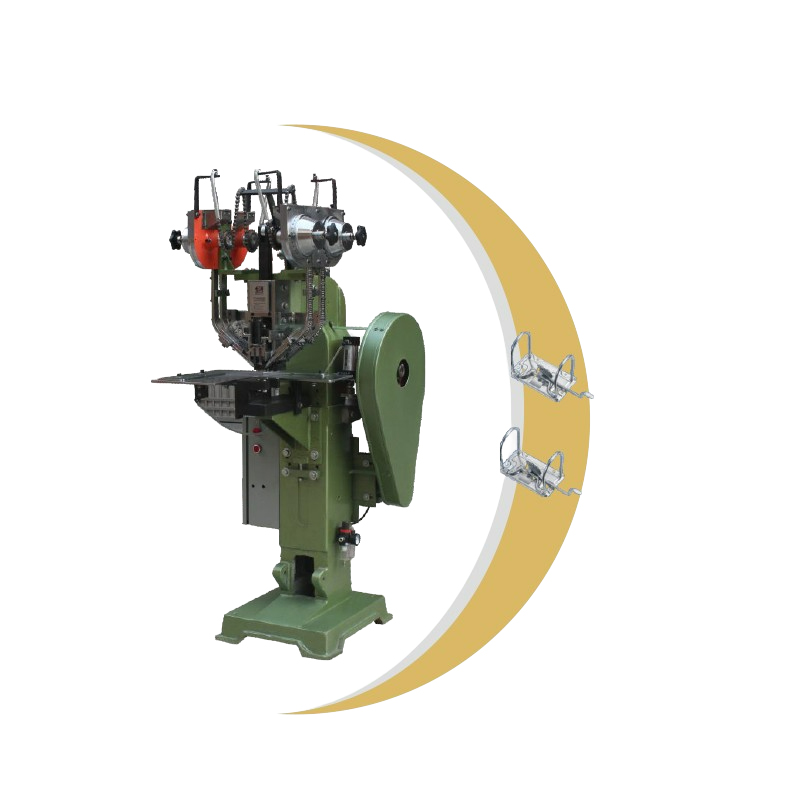

Tsis Siv Neeg Punching Tshuab rau Hlau Snap Button / Hollow Rivet UaJZ-9810

Daim ntawv thov

Tsis siv neeg xuas nrig ntaus tshuab yog tsim rau nruam stamping hlau ntawv, tooj liab ntawv, txhuas ntawv, stainless hlau thiab lwm yam khoom, lub tshuab nrog tsis siv neeg manipulator, tsis siv neeg feeder, thaum muaj xwm ceev braking system, crankshaft, txuas pas nrig thiab laub kav thiab lwm yam yog siv. rau bearing kev sib hloov, kom ruaj khov thiab txhim khu kev qha ua haujlwm.Nws tuaj yeem siv dav hauv cov khoom siv kho vajtse, cov nyees khawm hlau, qhov chaw pib, hluav taws xob plug-ins thiab lwm yam kev lag luam.

Feature

1.Punching tshuab muaj nws pib-yob feeder, nws pib pub cradle, thiab scrap roller.Nws yog ib qho yooj yim rau kev khiav lag luam thiab nws khiav ceev, thiab nws yog tsis siv neeg los ntawm cov khoom noj rau dov seem.

2.Progressive pwm yog ua los ntawm kev thov.Tungsten carbide yog siv los ua ib feem ntawm pwm cov pwm yog resistant rau hnav thiab tsim kua muag.

3.Auto pub menyuam txaj muaj ob qhov chaw-lub cev lub cev tshuab ua haujlwm ntau dua thiab nrawm dua;Kev kub ceev hlau khawm ntau lawm kab ua rau lub caij nplooj ntoos hlav prong stud, Caij nplooj ntoos hlav prong socket, prong snap khawm, ris tsho khawm, rivets, xaws khawm, hollow rivet, eyelet / grommet, ib lub hau rivet, tus me nyuam nyees khawm ua;

4.High zog steel welded lub cev, tempering kho, siab rigidity, raug thiab stability.

5.Qhov chaw kis tau tus mob: lub iav txais kaw kev sib kis, thiab los ntawm kev sib tsoo pov tseg, poob roj du, sib npaug sib npaug, tsis tshua muaj suab nrov, lub neej ntev.

6.Lub meshing nto thiab tsis sib haum xeeb khub nyob rau hauv lub tsiv qhov chaw tshwj xeeb yog kho nrog intermediate zaus, nto hardening, nitriding, thiab lwm yam., extending thiab guaranteeing lub neej kev pab cuam ntawm lub tshuab cuab yeej.

7.Dry pneumatic tsis sib haum xeeb nres yog xaiv, qhov layout, tsis sib haum xeeb phaj tiv thaiv hloov yooj yim, yooj yim kho.

8.Nrog kev ua haujlwm siab, tsis tshua muaj suab nrov, lub neej ntev thiab lwm yam tseem ceeb.